Everything You Need To Know About Curb and Corporation Stops

Curb and corporation stops often cause as much confusion as they do answers for fast and effective water shut off. What’s the difference between them? What are the different types? In this post, we’ll cover what you need to know about curb stops and corporation stops so that you can apply that knowledge effectively in the field.

What’s the Difference?

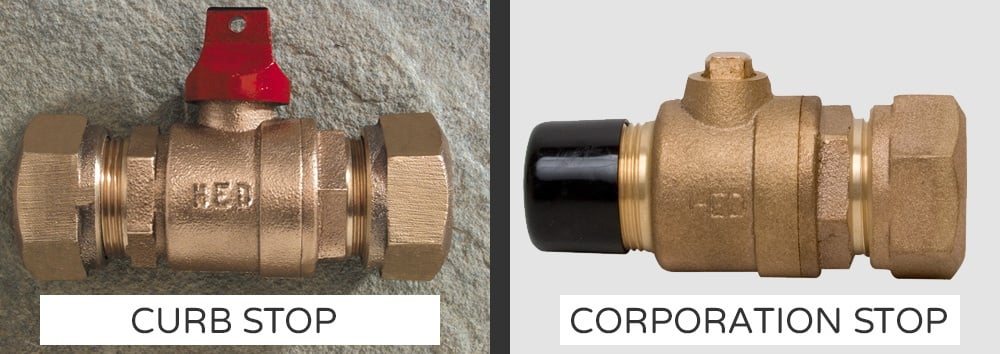

The first difference between these two types is its location, with a corporation stop being located directly attached to the main while curb stops are typically located in the sidewalk or on the home or business property. Beyond that, the corporation stop is designed to be installed while the main is under pressure, featuring a body shape, operating valve and driving threads designed to be installed with a tapping machine. This allows you to install the valve without interrupting service. Once the curb valve is installed, the corporation valve is buried under backfill and is inaccessible without a lot of work.

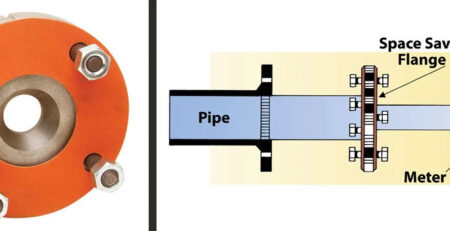

By comparison, a curb valve is located between the corporation valve and the new service structure, a service style box is installed over the curb stop which allows easy access to shutoff or turn on water going into a building or residence. Though this is quite often the last master shutoff valve in the system, some locations will have a meter valve or secondary shutoff valve located within the structure itself.

How are Traditional and Minneapolis Pattern Curb Stops Different?

Most curb stops are fairly straightforward, but there are a couple differences. Specifically, a traditional and Minneapolis pattern curb stop have significant differences in the curb box that is used. Once a curb stop is installed, it needs a curb box attached which acts as a conduit to allow fast and easy access to the valve without a lot of digging or debris removal. This can happen in one of two ways. A traditional curb box is an arched, cast iron structure that is used on a standard curb box, placed over the top of the curb stop to protect it and improve access in the future. A Minneapolis pattern curb stop, on the other hand, features a special curb box that can be threaded onto a Minneapolis pattern curb stop as it’s installed. Because the stop and curb box are now connected, they have a better seal, which reduces debris infiltration and the chance that the box will shift due to backfilling or a frost heave. The visual difference is that a Minneapolis pattern curb stop will have threads that have been cut into the valve stem area for the box to attach, while a traditional curb stop will lack threads in this area.

As you can see, there are some significant differences between curb and corporation stops and the different types of curb stops. This means you need to know what you’re working with before you start excavating and changing out components or you may find that you have the wrong type of stop or curb box for the job.