Red Hed Comes Through for Our Clients: Customized Specialty Flanges

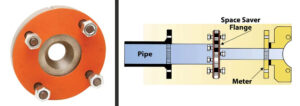

It’s fairly common in the waterworks industry to step from one pipe size to another, typically using a single flange or a series of fittings to make the connection happen. What if you need to fit the diameter change into a small area? We have a number of space saver flanges that help make the transition in the space needed, as it combines both connections in a single plate. But what can you do when you have a specialty situation that needs a different approach? At Team Red Hed Manufacturing, we believe in providing customized solutions for our clients when they’re needed. Here’s the story of how we helped solve a unique problem for an upcoming bid.

One of our partner companies contacted us with a unique problem for an upcoming meter bid, hoping we could help them find a solution to the problem. The bid customer had existing 2″ oval meters which had a lay length of 17″. Easy, right? However, they wanted to change the meters out. In the place of the existing configuration, they wanted to place a 2″ turbo meter that had a lay length of 9″ and had a 4-bolt pattern to boot. The bid customer wanted to leave the existing piping and flanges in place to avoid the excess cost and time of replacing them.

Though this is often a simple process of using a range of fittings to reach the correct size and the correct length with filler pieces, this was not what the customer wanted in this conversion. Instead, they wanted a single piece of conversion material. It also needed to have a powder epoxy coating and have everything in one kit at a low enough cost that they could afford to use the single conversion piece on the many meters they had to replace in town.

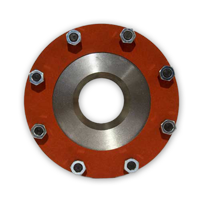

Red Hed Manufacturing came through by developing a customized specialty flange to meet the bid customer’s needs. We contacted our local foundry and had a pattern made that incorporated the necessary ends with the length created to fill in the gap crossing the 17″ to 9″ lay length. A casting was then poured, which was put in the CNC machine at Red Hed’s shop. This allowed us to then machine the special flange that met the customer’s exact needs for the project.

Once the customized flange was machined, it was sent to our coating specialist so that it could be coated with a powdered epoxy.

We packaged the customized specialty flange with the necessary gaskets, nuts and bolts to complete the kit. It could then be sent to the bid customer, who could simply grab a box off the shelf and have everything they needed at hand to install the new turbo meters without any problems.

Having access to a customized solution can make what seems like an impossible or difficult problem easy to complete. Whether you need a customized specialty flange or just a space saving flange to avoid excess reworking of pipes, you don’t have to settle for a lot of extra work. Red Hed Manufacturing has your back. Please feel free to contact us today for more information about our specialty flanges or customized solutions to your water utility challenges.