Do you Really Need a Thermal Coil Pit Instead of a Standard Pit?

If your town specifies thermal coil pits for meters and service valves, do you really need them? Thermal coil pits have become a common specification in a number of towns in cold climates, but they’re not really needed. But how are these types of pits different and why is it okay to argue for the use of a standard pit in areas where the specifications call for a thermal coil pit? Here’s a quick comparison with more information to get you started.

Generally speaking, a demand for thermal coil pits only come from an instance where a standard meter pit was incorrectly installed. In this article, we’re providing you with the truth behind standard pits and how you can use them effectively in your climate.

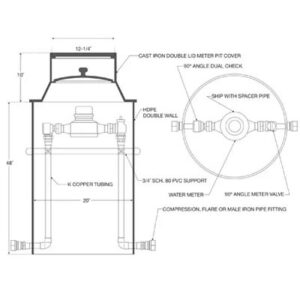

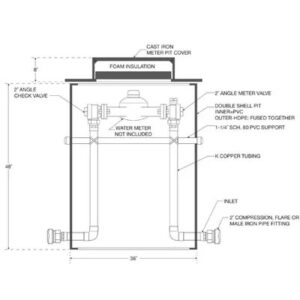

A thermal coil pit involves having a platform on which the meter sits and a pair of hoses that are coiled beneath it to make it possible to raise and lower the meter to be able to read it instead of having it hung at a more reasonable depth. The premise behind the thermal coil pit is that the meter will be warmer near the bottom of the pit than at the top, but this is not true. The air in the pit is all very close to the same temperature, therefore the meter is at no further risk of freezing at the top of the pit than at the bottom. It’s the unfrozen earth at the bottom of the pit that keeps the entire enclosure warm. They’re also only about 15″ wide, making repairing or replacing the hoses in the bottom virtually impossible without uninstalling the entire unit.

Standard meter pits that are produced by Red Hed are created from HDPE plastic, which has mild insulative properties. They can be created to any height with risers from our pit manufacturer. The white interior of the pit makes it simple to see the meter inside, read the meter and be on your way again. It’s sealed with a plastic insert to keep out dirt and water. As long as the bottom of the tough HDPE shell is deep enough to reach below the frost line, you’ll never have a problem with your meters freezing. For 5/8″ to 1″ meters, we use a 20″ diameter shell for our pits. For 1.5″ to 2″ meters, we expand this size to 36″. This gives you plenty of room to work freely.

Though thermal coil pits may be specified due to poor performance by standard pits in the past, proper installation makes this a moot point. Instead of spending a lot of money trying to purchase a thermal coil pit for your next installation, why not try a standard pit to see how much easier it is to install? If you have any questions, the professionals at Team Red Hed are standing by to help. Please feel free to contact our experienced associates today for more information, with any questions or to place an order for some of our high-quality water utility products.